Belts & Discs

Abrasive belts & discs are used for either grinding (metal removal) or finishing (scratch removal). Ceramic Grain is most often used for metal removal while Compact Grain is best for scratch removal.

Send us a description of the belt or disc you are using with its application and we will send you NO CHARGE SAMPLES.

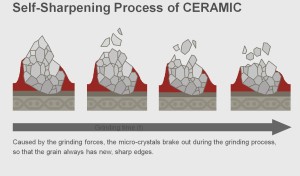

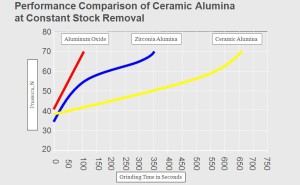

Ceramic Grain

Ceramic grain is most often used for grinding. Ceramic Grain is self-sharpening, meaning it fractures to provide a continuous, aggressive cut rate. This allows for higher stock removal. Ceramic grain enables belts & discs to cut faster and last longer. This subsequently saves time and money.

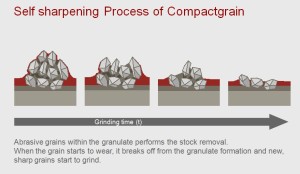

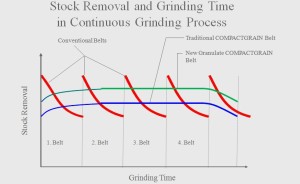

Compact Grain

Compact grain is most often used for finishing. Compact Grain is a self-sharpening ball of grains. Picture it this way; if normal belts or discs were coated with a single layer of snowflakes, then Compact Grain would be coated with a single layer of snowballs. The breakdown of Compact Grain is similar to a grinding wheel in that it provides a consistent finish over a very long life. Therefore, quality is improved while costs are reduced. That sounds like a win/win!